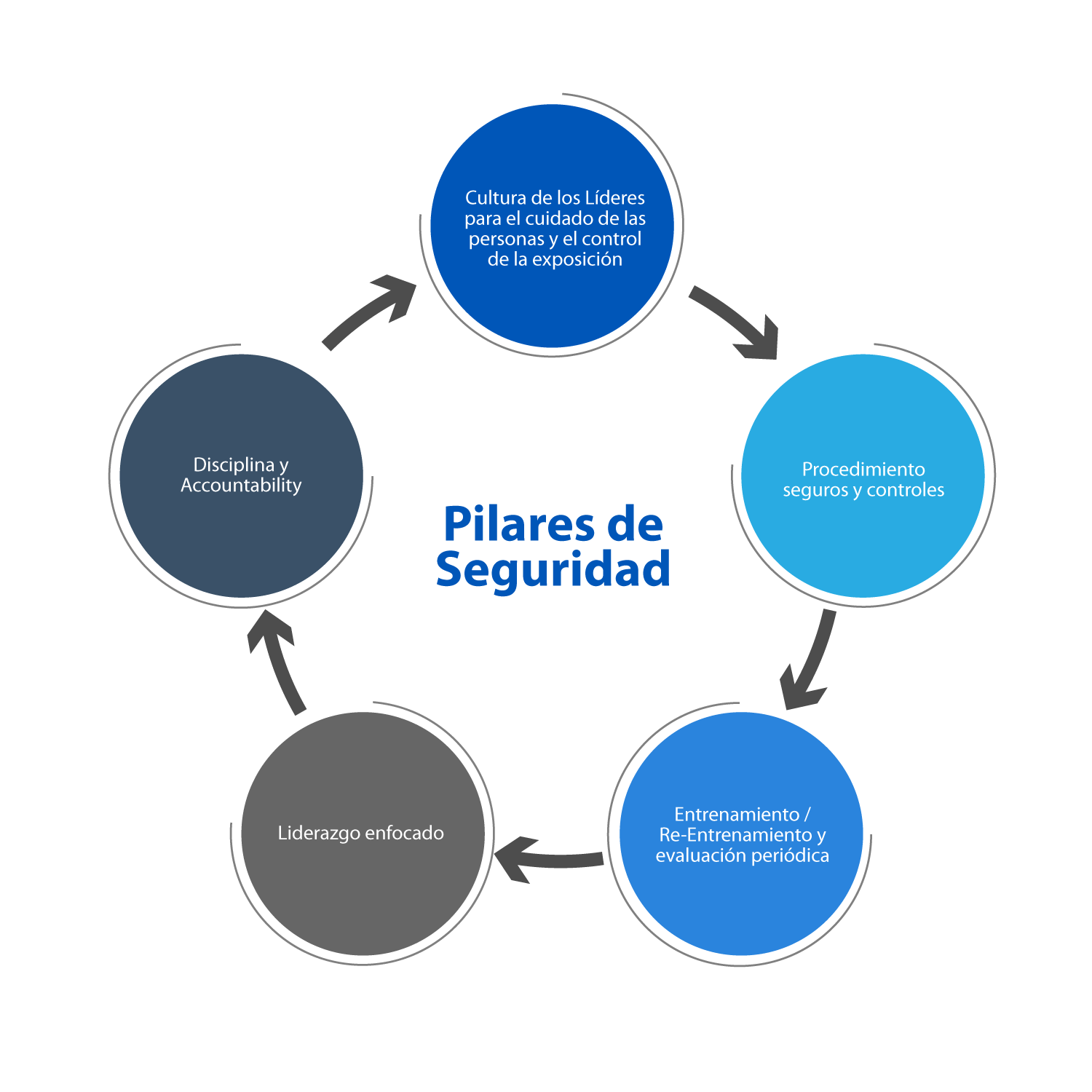

Our focus is on working with leaders, through the implementation of a leadership program that seeks to reduce exposure to hazardous situations and conditions, and to improve our culture of safety.

This program seeks to reinforce team bonding to establish safe behaviors and conditions. The program started in 2022 with three goals:

- Safety coommunication between leaders and workers

- Work sessions with teams to reinforce behaviors and work standards

- Physical risk inspections

- Coaching

This program is in addition to the behavior-based safety program implemented for the past five years.

Like everything else, we strive to improve our zero-harm culture. In 2023, a Safety Culture Measurement will be conducted.